The Engine Vibration Monitoring Unit (EVMU) is a crucial component of the Airbus A320 aircraft. It plays a vital role in monitoring and detecting any abnormal vibrations that may occur in the engines during flight. This advanced system utilizes various sensors and sophisticated algorithms to collect data on engine performance and vibrations. By analyzing this data, the EVMU can provide valuable insights into the health and condition of the aircraft’s engines, helping maintenance crews detect and address potential issues before they escalate.

Engine vibrations can be caused by a variety of factors, including unbalanced components, worn bearings, or even the ingestion of foreign objects. These vibrations can have a detrimental effect on engine performance and, if left undetected, can lead to serious problems or even engine failure. Therefore, the EVMU serves as a critical tool in ensuring the safety and reliability of the Airbus A320.

Contents

How Does the Engine Vibration Monitoring Unit Work?

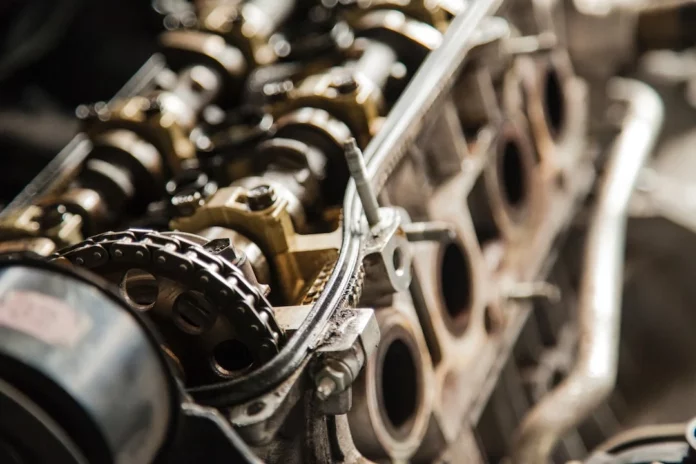

The Engine Vibration Monitoring Unit uses a combination of accelerometers and strain gauges to measure vibrations in the engines. These sensors are strategically placed at various points on the engine structure, allowing them to detect and measure vibrations in different directions and frequencies. The collected vibration data is then processed by the EVMU, which compares it to established thresholds and mathematical models to determine the severity of the vibrations.

When the EVMU detects vibrations that exceed the predetermined thresholds, it triggers an alert that notifies maintenance crews of the need for further investigation. This early-warning system allows technicians to identify and address the underlying issues that may be causing the abnormal vibrations. By taking timely corrective action, potential engine failures or performance issues can be prevented, minimizing aircraft downtime and ensuring a higher level of safety and efficiency.

The Benefits of the Engine Vibration Monitoring Unit

The Engine Vibration Monitoring Unit offers several key benefits for Airbus A320 operators and maintenance crews. Let’s explore some of these advantages:

1. Early Detection of Issues

By continuously monitoring engine vibrations, the EVMU enables the early detection of potential issues. Its ability to identify abnormal vibrations allows maintenance crews to intervene before a minor problem turns into a major one. This proactive approach not only helps prevent costly engine repairs but also ensures the safety and reliability of the aircraft.

The early detection of issues also minimizes aircraft downtime. Instead of waiting for a breakdown or failure, technicians can address and resolve the problem during scheduled maintenance, reducing the impact on the airline’s operations.

2. Enhanced Safety

The EVMU plays a crucial role in enhancing the safety of the Airbus A320. By continuously monitoring engine vibrations, it helps identify potential risks and allows for timely maintenance actions. This not only ensures the reliability of the aircraft but also reduces the likelihood of in-flight engine failures, which could have catastrophic consequences.

Furthermore, the EVMU contributes to the overall aviation safety by providing valuable data for trend analysis. The collected vibration data, when analyzed over a period of time, can reveal patterns or changes in engine behavior, allowing for preventive maintenance measures to be implemented. This helps in identifying and addressing potential issues before they become a threat to aircraft safety.

3. Improved Engine Performance and Efficiency

Monitoring engine vibrations through the EVMU not only helps in maintaining safety but also contributes to improved engine performance and efficiency. By identifying and addressing the underlying causes of abnormal vibrations, maintenance crews can restore the engines to optimal operating conditions.

Minimizing vibrations improves the overall performance of the engines, reducing unnecessary stress on the components and increasing their lifespan. This, in turn, leads to lower maintenance costs and higher fuel efficiency, benefiting both the airline’s bottom line and the environment.

In conclusion, the Engine Vibration Monitoring Unit is a critical component of the Airbus A320 aircraft, providing continuous monitoring and detection of abnormal vibrations in the engines. By enabling proactive maintenance actions, enhancing safety, and improving engine performance and efficiency, the EVMU plays a significant role in ensuring the smooth and reliable operation of the aircraft. Its advanced monitoring capabilities help airlines and maintenance crews avoid costly repairs, reduce downtime, and prioritize the safety of passengers and crew.

For More: What is EIU on Airbus A320? (Engine Interface Unit)